Lithologic Reservoirs ›› 2026, Vol. 38 ›› Issue (1): 172-179.doi: 10.12108/yxyqc.20260115

• PETROLEUM ENGINEERING AND OIL & GAS FIELD DEVELOPMENT • Previous Articles

Numerical simulation on the coupling of flow and geomechanics during CO2 huff and puff in shale oil reservoirs

ZHANG Qingfu( ), ZHANG Shiming, CAO Xiaopeng, LYU Qi, LI Zongyang, YU Jinbiao, WANG Yong

), ZHANG Shiming, CAO Xiaopeng, LYU Qi, LI Zongyang, YU Jinbiao, WANG Yong

Exploration and Development Research Institute ,Sinopec Shengli Oilfield Company Dongying 257015, Shandong, China

CLC Number:

- TE349

| [1] | 苏皓, 雷征东, 张荻萩, 等. 致密油藏体积压裂水平井参数优化研究[J]. 岩性油气藏, 2018, 30(4):140-148. |

| SU Hao, LEI Zhengdong, ZHANG Diqiu, et al. Volume fractu-ring parameters optimization of horizontal well in tight reservoir[J]. Lithologic Reservoirs, 2018, 30(4):140-148. | |

| [2] |

李继庆, 刘曰武, 黄灿, 等. 页岩气水平井试井模型及井间干扰特征[J]. 岩性油气藏, 2018, 30(6):138-144.

doi: 10.12108/yxyqc.20180617 |

|

LIU Jiqing, LIU Yuewu, HUANG Can, et al. Multi-stage fracturing horizontal well interference test model and its application[J]. Lithologic Reservoirs, 2018, 30(6):138-144.

doi: 10.12108/yxyqc.20180617 |

|

| [3] |

刘博, 徐刚, 纪拥军, 等. 页岩油水平井体积压裂及微地震监测技术实践[J]. 岩性油气藏, 2020, 32(6):172-180.

doi: 10.12108/yxyqc.20200617 |

|

LIU Bo, XU Gang, JI Yongjun, et al. Practice of volume fractu-ring and microseismic monitoring technology in horizontal wells of shale oil[J]. Lithologic Reservoirs, 2020, 32(6):172-180.

doi: 10.12108/yxyqc.20200617 |

|

| [4] |

HUGHES J D. A reality check on the shale revolution[J]. Nature, 2013, 494(7437):307-308.

doi: 10.1038/494307a |

| [5] | CLARK A J. Determination of recovery factor in the Bakken Formation,Mountrail county,ND[R]. New Orlean,SPE Annual Technical Conference and Exhibition, 2009. |

| [6] | 刘佳慧, 苏玉亮, 李蕾, 等. 基于微流控实验的页岩油CO2吞吐提高采收率微观机理研究[R]. 西安,油气田勘探与开发国际会议, 2022. |

| LIU Jiahui, SU Yuliang, LI Lei, et al. Study on micro mechanism of enhanced oil recovery by CO2 huff-n-puff of shale oil based on microfluidic experiment[R]. Xi’an,The International Field Exploration & Development Conference, 2022. | |

| [7] | 杨明, 薛程伟, 李朝阳, 等. 页岩油CO2吞吐影响因素及微观孔隙动用特征[J]. 大庆石油地质与开发, 2023, 42(4):148-156. |

| YANG Ming, XUE Chengwei, LI Chaoyang, et al. Influencing factors of CO2 huff and puff and micro-pores producing characteristics of shale oil[J]. Petroleum Geology & Oilfield Development in Daqing, 2023, 42(4):148-156. | |

| [8] | 李凤霞, 王海波, 周彤, 等. 页岩油储层裂缝对CO2吞吐效果的影响及孔隙动用特征[J]. 石油钻探技术, 2022, 50(2):38-44 |

| LI Fengxia, WANG Haibo, ZHOU Tong, et al. The influence of fractures in shale oil reservoirs on CO2 huff and puff and its pore production characteristics[J]. Petroleum Drilling Techni-ques, 2022, 50(2):38-44. | |

| [9] | 叶安平, 郭平, 王绍平, 等. 利用PR状态方程确定CO2驱最小混相压力[J]. 岩性油气藏, 2012, 24(6):125-128. |

| YE Anping, GUO Ping, WANG Shaoping, et al. Determination of minimum miscibility pressure for CO2 flooding by using PR equation of state[J]. Lithologic Reservoirs, 2012, 24(6):125-128. | |

| [10] | 张海龙. CO2混相驱提高石油采收率实践与认识[J]. 大庆石油地质与开发, 2020, 39(2):114-119. |

| ZHANG Hailong. Practice and understanding of enhancing the oil recovery by CO2 miscible flooding[J]. Petroleum Geology & Oilfield Development in Daqing, 2020, 39(2):114-119. | |

| [11] |

程杰成, 朱维耀, 姜洪福. 特低渗透油藏CO2驱油多相渗流理论模型研究及应用[J]. 石油学报, 2008, 29(2):246-251.

doi: 10.7623/syxb200802016 |

|

CHENG Jiecheng, ZHU Weiyao, JIANG Hongfu. Study on mathematical models for multi-phase porous flow in CO2 drive of extra-low permeability reservoir and field application[J]. Acta Petrolei Sinica, 2008, 29(2):246-251.

doi: 10.7623/syxb200802016 |

|

| [12] |

周瑞, 苏玉亮, 马兵, 等. 随机分形体积压裂水平井CO2吞吐模拟[J]. 岩性油气藏, 2020, 32(1):161-168.

doi: 10.12108/yxyqc.20200118 |

|

ZHOU Rui, SU Yuliang, MA Bing, et al. CO2 huff and puff simulation in horizontal well with random fractal volume fracturing[J]. Lithologic Reservoirs, 2020, 32(1):161-168.

doi: 10.12108/yxyqc.20200118 |

|

| [13] | GAMADI T D, ELLDAKLI F, SHENG J J. Compositional simulation evaluation of EOR potential in shale oil reservoirs by cyclic natural gas injection[R]. Denver,SPE/AAPG/SEG Unconventional Resources Technology Conference, 2014. |

| [14] | YU Wei, LASHGARI H, SEPEHRNOORI K. Simulation study of CO2 huff-n-puff process in Bakken tight oil reservoirs[R]. Denver,SPE Western North American and Rocky Mountain Joint Meeting, 2014. |

| [15] |

LI Sheng, DONG Mingzhe, LUO Peng. Simulation study on dissolved oil release from kerogen and its effect on shale oil production under primary depletion and CO2 huff-n-puff[J]. Journal of Petroleum Science and Engineering, 2021, 200:108239.

doi: 10.1016/j.petrol.2020.108239 |

| [16] | DENOYELLE L C, LEMONNIER P. Simulation of CO2 huff and puff using relative permeability hysteresis[R]. Dallas,SPE Annual Technical Conference and Exhibition, 1987. |

| [17] |

WAN T, SHENG J J. Evaluation of the EOR potential in hydraulically fractured shale oil reservoirs by cyclic gas injection[J]. Petroleum Science and Technology, 2015, 33(7):812-818.

doi: 10.1080/10916466.2015.1010041 |

| [18] |

MOLERO P Z, YU Wei, XU Yifei, et al. Simulation study of CO2-EOR in tight oil reservoirs with complex fracture geo-metries[J]. Scientific Reports, 2016, 6:33445.

doi: 10.1038/srep33445 |

| [19] | 张英林. 页岩油藏储集性能及应力敏感性评价[D]. 青岛: 中国石油大学(华东), 2020. |

| ZHANG Yinglin. Evaluation of reservoir property and stress sensitivity in shale reservoir[D]. Qingdao: China University of Petroleum (East China), 2020. | |

| [20] |

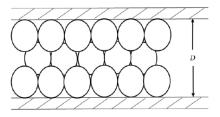

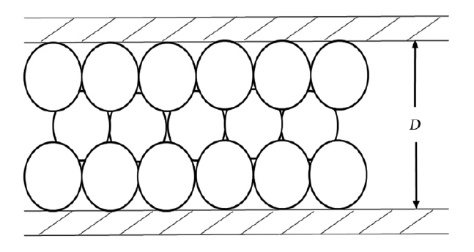

LI Kewen, GAO Yuanping, LYU Youchang, et al. New mathe-matical models for calculating proppant embedment and fracture conductivity[J]. SPE Journal, 2015, 20(3):496-507.

doi: 10.2118/155954-PA |

| [21] | LACY L L, RICKARDS A R, BLLDEN D M. Fracture width and embedment testing in soft reservoir sandstone[J]. SPE drilling & completion, 1998, 13(1):25-29. |

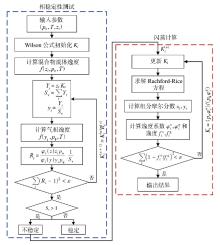

| [22] | 张庆福. 页岩油藏注CO2增能开发数值模拟研究[J]. 计算力学学报, 2024, 41(4):755-761. |

| ZHANG Qingfu. Numerical simulation of CO2-EOR in shale oil reservoirs[J]. Chinese Journal of Computational Mechanics, 2024, 41(4):755-761. | |

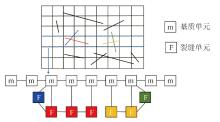

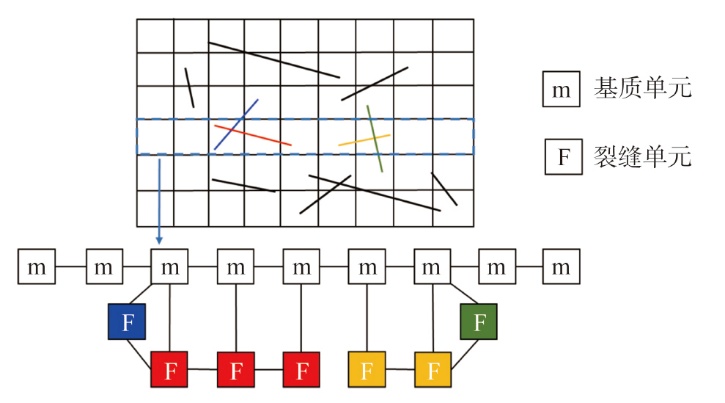

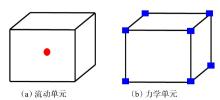

| [23] | 刘礼军. 缝洞型碳酸盐岩油气藏流固耦合数值模拟研究[D]. 青岛: 中国石油大学(华东), 2021. |

| LIU Lijun. Numerical simulation of coupled flow and geomechanical process in fractured karst carbonate reservoirs[D]. Qingdao: China University of Petroleum (East China), 2021. |

|

||