岩性油气藏 ›› 2026, Vol. 38 ›› Issue (1): 180–190.doi: 10.12108/yxyqc.20260116

• 石油工程与油气田开发 • 上一篇

页岩油储层前置CO2压裂液体滞留效应研究进展

张衍君1( ), 刘拯君1, 徐豪1, 贺文杰1, 刘亚茹2, 邢亮3, 周德胜1, 王祯1

), 刘拯君1, 徐豪1, 贺文杰1, 刘亚茹2, 邢亮3, 周德胜1, 王祯1

- 1

西安石油大学 石油工程学院 西安 710065

2中国石化临汾煤层气分公司 山西 临汾 041000

3河北工程大学 机械与装备工程学院 河北 邯郸 056038

Research progress on retention effects of pre-CO2 fracturing fluid of shale oil reservoirs

ZHANG Yanjun1( ), LIU Zhengjun1, XU Hao1, HE Wenjie1, LIU Yaru2, XING Liang3, ZHOU Desheng1, WANG Zhen1

), LIU Zhengjun1, XU Hao1, HE Wenjie1, LIU Yaru2, XING Liang3, ZHOU Desheng1, WANG Zhen1

- 1

College of Petroleum Engineering ,Xi’an Shiyou University Xi’an 710065, China

2Linfen Coalbed Methane Branch ,Sinopec, Linfen 041000 Shanxi, China

3School of Mechanical and Equipment Engineering ,Hebei University of Engineering, Handan 056038 Hebei, China

摘要:

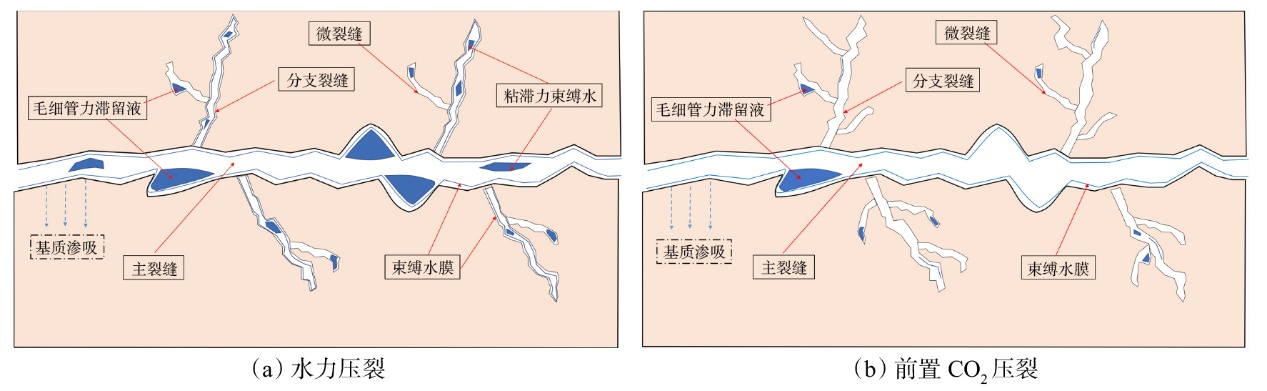

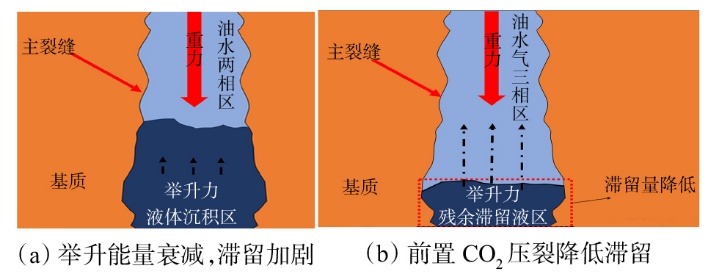

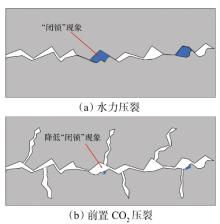

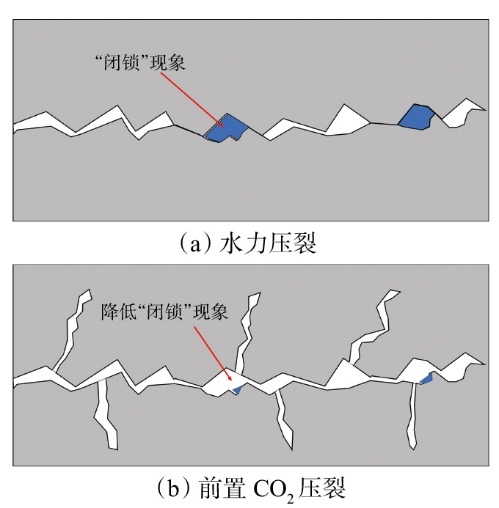

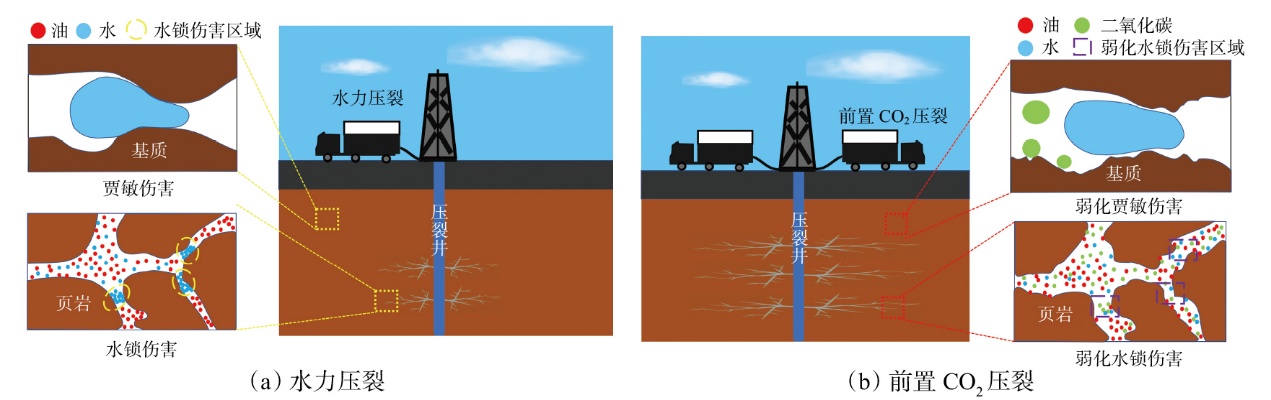

利用前置CO2压裂技术开发页岩油储层优势明显,能够降低储层伤害、提高缝网复杂度及油气动用程度。通过大量文献调研和系统梳理,总结了前置CO2压裂液体滞留机理及引起的储层物理-化学性质变化,并讨论了前置CO2压裂液体滞留效应的阶段性及压裂工艺的适用性。研究结果表明:①页岩油储层前置CO2压裂液滞留机理主要包括多级裂缝网络滞留、近缝面基质渗吸滞留、物理-化学作用引起滞留;主裂缝中重力主导滞留,分支及微裂缝的“闭锁”效应明显。②液体滞留引起储层物理-化学性质变化包括促进缝网形成、弱化水相圈闭、基质孔隙增压;CO2通过影响表面张力进而影响近缝面基质液体的滞留,其强扩散效果及对岩石的溶蚀作用有利于形成复杂裂缝网络,以改善岩石的渗透性。③前置CO2压裂液体滞留效应在裂缝扩展、闷井、返排、生产4个阶段差异明显,未来需加强前置CO2压裂技术的迭代升级,发挥CO2驱油与封存协同优势,发展智能调控优化储层多介质协同注入策略,实现油气增产与碳中和共同发展。

中图分类号:

- TE357

| [1] |

孙龙德, 贾承造, 张君峰, 等. 松辽盆地古龙页岩油重点地区资源潜力[J]. 石油学报, 2024, 45(12):1699-1714.

doi: 10.7623/syxb202412001 |

|

SUN Longde, JIA Chengzao, ZHANG Junfeng, et al. Resource potential of Gulong shale oil in the key areas of Songliao Basin[J]. Acta Petrolei Sinica, 2024, 45(12):1699-1714.

doi: 10.7623/syxb202412001 |

|

| [2] |

张记刚, 杜猛, 陈超, 等. 吉木萨尔凹陷二叠系芦草沟组页岩储层孔隙结构定量表征[J]. 岩性油气藏, 2022, 34(4):89-102.

doi: 10.12108/yxyqc.20220409 |

|

ZHANG Jigang, DU Meng, CHEN Chao, et al. Quantitative characterization of pore structure of shale reservoirs of Permian Lucaogou Formation in Jimsar Sag[J]. Lithologic Reservoirs, 2022, 34(4):89-102.

doi: 10.12108/yxyqc.20220409 |

|

| [3] |

徐田录, 吴承美, 张金凤, 等. 吉木萨尔凹陷二叠系芦草沟组页岩油储层天然裂缝特征与压裂模拟[J]. 岩性油气藏, 2024, 36(4):35-43.

doi: 10.12108/yxyqc.20240404 |

|

XU Tianlu, WU Chengmei, ZHANG Jinfeng, et al. Natural fracture characteristics and fracture network simulation in shale reservoirs of Permian Lucaogou Formation in Jimsar Sag[J]. Lithologic Reservoirs, 2024, 36(4):35-43.

doi: 10.12108/yxyqc.20240404 |

|

| [4] | 张衍君, 徐树参, 刘娅菲, 等. 吉木萨尔页岩油压裂开发压后闷井时间优化[J]. 新疆石油天然气, 2023, 19(1):1-7. |

| ZHANG Yanjun, XU Shucan, LIU Yafei, et al. Optimization of well shut-in time after fracturing in Jimusar shale oil reservoirs[J]. Xinjiang Oil & Gas, 2023, 19(1):1-7. | |

| [5] |

MCMAHON T P, LARSON T E, ZHANG T, et al. Geologic characteristics, exploration and production progress of shale oil and gas in the United States:An overview[J]. Petroleum Exploration and Development, 2024, 51(4):925-948.

doi: 10.1016/S1876-3804(24)60516-1 |

| [6] | 张廷山, 彭志, 杨巍, 等. 美国页岩油研究对我国的启示[J]. 岩性油气藏, 2015, 27(3):1-10. |

|

ZAHNG Tingshan, PENG Zhi, YANG Wei, et al. Enlightenments of American shale oil research towards China[J]. Lithologic Reservoirs, 2015, 27(3):1-10.

doi: 10.3969/j.issn.1673-8926.2015.03.001 |

|

| [7] |

雷群, 翁定为, 管保山, 等. 基于缝控压裂优化设计的致密油储集层改造方法[J]. 石油勘探与开发, 2020, 47(3):592-599.

doi: 10.11698/PED.2020.03.15 |

| LEI Qun, WENG Dingwei, GUAN Baoshan, et al. A novel approach of tight oil reservoirs stimulation based on fracture controlling optimization and design[J]. Petroleum Exploration and Development, 2020, 47(3):592-599. | |

| [8] |

ZOU Yushi, ZHANG Shicheng, ZHOU Tong, et al. Experimental investigation into hydraulic fracture network propagation in gas shales using CT scanning technology[J]. Rock Mechanics and Rock Engineering, 2016, 49(1):33-45.

doi: 10.1007/s00603-015-0720-3 |

| [9] |

曾凡辉, 张蔷, 郭建春, 等. 页岩水化及水锁解除机制[J]. 石油勘探与开发, 2021, 48(3):646-653.

doi: 10.11698/PED.2021.03.20 |

| ZENG Fanhui, ZHANG Qiang, GUO Jianchun, et al. Mechanisms of shale hydration and water block removal[J]. Petroleum Exploration and Development, 2021, 48(3):646-653. | |

| [10] |

刘赛, 娄清香, 刘雯雯, 等. 强水敏致密砾岩储层压裂液侵入伤害实验[J]. 岩性油气藏, 2025, 37(4):192-200.

doi: 10.12108/yxyqc.20250418 |

|

LIU Sai, LOU Qingxiang, LIU Wenwen, et al. Experiment on damage of fracturing fluid in strong water-sensitive tight conglomerate reservoir[J]. Lithologic Reservoirs, 2025, 37(4):192-200.

doi: 10.12108/yxyqc.20250418 |

|

| [11] | 陈丽华. 强水敏储层矿物高温变化对储层物性的影响:以金家油田沙一段为例[J]. 岩性油气藏, 2016, 28(4):121-126. |

| CHEN Lihua. Influence of thermal alteration of minerals in strong water sensitive reservoir on physical properties:A case study from the first member of Shahejie Formation in Jinjia Oilfield[J]. Lithologic Reservoirs, 2016, 28(4):121-126. | |

| [12] | 王海军, 邓媛, 段春节, 等. 大牛地气田储层伤害研究[J]. 岩性油气藏, 2010, 22(4):125-129. |

| WANG Haijun, DENG Yuan, DUAN Chunjie, et al. Study on reservoir damage in Daniudi Gasfield[J]. Lithologic Reservoirs, 2010, 22(4):125-129. | |

| [13] |

李阳, 祝仰文, 李宗阳, 等. 济阳坳陷页岩油注二氧化碳开发技术[J]. 石油勘探与开发, 2024, 51(4):855-864.

doi: 10.11698/PED.20240216 |

| LI Yang, ZHU Yangwen, LI Zongyang, et al. Shale oil recovery by CO2 injection in Jiyang Depression,Bohai Bay Basin,East China[J]. Petroleum Exploration and Development, 2024, 51(4):855-864. | |

| [14] |

杨兆臣, 卢迎波, 杨果, 等. 中深层稠油水平井前置CO2蓄能压裂技术[J]. 岩性油气藏, 2024, 36(1):178-184.

doi: 10.12108/yxyqc.20240117 |

|

YANG Zhaochen, LU Yingbo, YANG Guo, et al. Pre-CO2 energy storage fracturing technology in horizontal wells for medium-deep heavy oil[J]. Lithologic Reservoirs, 2024, 36(1):178-184.

doi: 10.12108/yxyqc.20240117 |

|

| [15] |

WANG Lu, ZHANG Yifan, ZOU Rui, et al. A systematic review of CO2 injection for enhanced oil recovery and carbon storage in shale reservoirs[J]. International Journal of Hydrogen Energy, 2023, 48(95):37134-37165.

doi: 10.1016/j.ijhydene.2023.06.099 |

| [16] |

胡永乐, 郝明强, 陈国利, 等. 中国CO2驱油与埋存技术及实践[J]. 石油勘探与开发, 2019, 46(4):716-727.

doi: 10.11698/PED.2019.04.10 |

| HU Yongle, HAO Mingqiang, CHEN Guoli, et al. Technologies and practice of CO2 flooding and sequestration in China[J]. Petroleum Exploration and Development, 2019, 46(4):716-727. | |

| [17] |

XIA Yulei, LI Lei, WANG Zhe. Experimental and numerical study on influencing factors of replacement capacity and slickwater flowback efficiency using pre-CO2 fracturing in tight oil reservoirs[J]. Journal of Petroleum Science and Engineering, 2022, 215:110697.

doi: 10.1016/j.petrol.2022.110697 |

| [18] | 杨红, 王宏, 南宇峰, 等. 油藏CO2驱油提高采收率适宜性评价[J]. 岩性油气藏, 2017, 29(3):140-146. |

|

YANG Hong, WANG Hong, NAN Yufeng, et al. Suitability evalua-tion of enhanced oil recovery by CO2 flooding[J]. Lithologic Reservoirs, 2017, 29(3):140-146.

doi: 10.3969/j.issn.1673-8926.2017.03.017 |

|

| [19] | 李阳, 赵清民, 杨勇, 等. 胜利油田陆相页岩油前置CO2压裂技术研究与实践[J]. 断块油气田, 2024, 31(6):945-954. |

| LI Yang, ZHAO Qingmin, YANG Yong, et al. Study and application of CO2 pre-fracturing technology of continental shale oil in Shengli Oilfield[J]. Fault-Block Oil & Gas Field, 2024, 31(6):945-954. | |

| [20] |

LI Sihai, ZHANG Shicheng, ZOU Yushi, et al. Experimental study on the feasibility of supercritical CO2-gel fracturing for stimulating shale oil reservoirs[J]. Engineering Fracture Mechanics, 2020, 238:107276.

doi: 10.1016/j.engfracmech.2020.107276 |

| [21] | KIZAKI A, TANAKA H, OHASHI K, et al. Hydraulic fractu-ring in inada granite and Ogino tuff with super critical carbon dioxide[R]. Seoul,International Society for Rock Mechanics and Rock Engineering, 2012. |

| [22] | 秦积舜, 韩海水, 刘晓蕾. 美国CO2驱油技术应用及启示[J]. 石油勘探与开发, 2015, 42(2):209-216. |

| QIN Jishun, HAN Haishui, LIU Xiaolei. Application and enlightenment of carbon dioxide flooding in the United States of America[J]. Petroleum Exploration and Development, 2015, 42(2):209-216. | |

| [23] |

杨勇, 张世明, 曹小朋, 等. 胜利油田CO2高压混相驱油与封存理论技术及矿场实践[J]. 石油勘探与开发, 2024, 51(5):1080-1091.

doi: 10.11698/PED.20240041 |

| YANG Yong, ZHANG Shiming, CAO Xiaopeng, et al. CO2 high-pressure miscible flooding and storage technology and its application in Shengli Oilfield,East China[J]. Petroleum Exploration and Development, 2024, 51(5):1080-1091. | |

| [24] | 邹雨时, 李彦超, 李四海. CO2前置注入对页岩压裂裂缝形态和岩石物性的影响[J]. 天然气工业, 2021, 41(10):83-94. |

| ZOU Yushi, LI Yanchao, LI Sihai. Influence of CO2 pre-injection on fracture mophology and the petrophysical properties in shale fracturing[J]. Natural Gas Industry, 2021, 41(10):83-94. | |

| [25] | 侯向前, 卢拥军, 张福祥, 等. CO2在非常规油气增产领域应用研究进展[J]. 油田化学, 2023, 40(2):356-362. |

| HOU Xiangqian, LU Yongjun, ZHANG Fuxiang, et al. Research progress on application of CO2 in unconventional oil and gas stimulation[J]. Oilfield Chemistry, 2023, 40(2):356-362. | |

| [26] |

WAN Tao, DING Kun, XIONG Qiyong, et al. The phase behavior of CO2 injection in shale reservoirs with nano-pores[J]. RSC Advances, 2024, 14(37):27227-27240.

doi: 10.1039/d4ra01239a pmid: 39193287 |

| [27] |

WANG Wei, LI Xinyu, WEI Zhikun, et al. Effect of CO2-brine-rock interactions on the pore structure of the tight sandstone during CO2 flooding:A case study of Chang 7 member of the Triassic Yanchang Formation in the Ordos Basin,China[J]. ACS Omega, 2023, 8(4):3998-4009.

doi: 10.1021/acsomega.2c06805 |

| [28] | 肖娜, 李实, 林梅钦. CO2-水-岩石相互作用对岩石孔渗参数及孔隙结构的影响:以延长油田35-3井储层为例[J]. 油田化学, 2018, 35(1):85-90. |

| XIAO Na, LI Shi, LIN Meiqin. Effect of CO2-water-rock interaction on porosity,permeability and pore structure characters of reservoir rock:A case study of 35-3 well in Yanchang Oilfield[J]. Oilfield Chemistry, 2018, 35(1):85-90. | |

| [29] |

崔传智, 李静, 吴忠维. 扩散吸附作用下CO2非混相驱微观渗流特征模拟[J]. 岩性油气藏, 2024, 36(6):181-188.

doi: 10.12108/yxyqc.20240617 |

|

CUI Chuanzhi, LI Jing, WU Zhongwei. Simulation of microscopic seepage characteristics of CO2 immiscible flooding under the effect of diffusion and adsorption[J]. Lithologic Reservoirs, 2024, 36(6):181-188.

doi: 10.12108/yxyqc.20240617 |

|

| [30] | 韩亚北. 液态二氧化碳相变致裂增透机理研究[D]. 焦作: 河南理工大学, 2014. |

| HAN Yabei. Mechanism research on increase coal gas permeability by liquid CO2 phase transition fracturing technique[D]. Jiaozuo: Henan Polytechnic University, 2014. | |

| [31] | 池圣平, 郎学军, 李赣勤, 等. CO2增能压裂工艺技术研究与应用[J]. 钻采工艺, 2005, 28(4):104-105. |

| CHI Shengping, LANG Xuejun, LI Ganqin, et al. Research and application of CO2 enhanced fracturing technology[J]. Drilling & Production Technology, 2005, 28(4):104-105. | |

| [32] | 赵坤, 李泽阳, 刘娟丽, 等. 吉木萨尔页岩油井区CO2前置压裂工艺参数优化及现场实践[J]. 油气藏评价与开发, 2024, 14(1):83-90. |

| ZHAO Kun, LI Zeyang, LIU Juanli, et al. Parameter optimization and field practice of CO2 pre-fracturing process in Jimsar shale oil block[J]. Petroleum Reservoir Evaluation and Deve-lopment, 2024, 14(1):83-90. | |

| [33] | ZHANG Yanjun, GE Hongkui, LIU Guangyu, et al. Experimental study of fracturing fluid retention in rough fractures[J]. Geo-fluids, 2019, 20:2603296. |

| [34] | PARMAR J S, DEHGHANPOUR H, KURU E. Drainage against gravity:Factors impacting the load recovery in fractures[R]. Woodlands,SPE Unconventional Resources Conference-USA, 2013. |

| [35] | 苏玉亮, 陈征, 唐梅荣, 等. 致密储层不同驱替方式下超临界CO2蓄能返排效果实验研究[J]. 油气地质与采收率, 2020, 27(5):79-85. |

| SU Yuliang, CHEN Zheng, TANG Meirong, et al. Experimental study of supercritical CO2 storage and flowback under different displacement methods in tight reservoirs[J]. Petroleum Geo-logy and Recovery Efficiency, 2020, 27(5):79-85. | |

| [36] |

LAKATOS I, LAKATOS-SZABÓ J. Effect of carbon dioxide on rheological properties and structure of polyacrylamide solutions[J]. Colloid Polymer Science, 1996, 274(10):959-965.

doi: 10.1007/BF00656625 |

| [37] | 陈晋阳, 郑海飞, 曾贻善. 高温下合成包裹体中流体水分子氢键的拉曼光谱分析[J]. 岩矿测试, 2002, 21(3):166-170. |

| CHEN Jinyang, ZHENG Haifei, ZENG Yishan. Raman spectroscopic study on hydrogen bond of water molecules in synthetic inclusions under high temperature[J]. Rock and Mineral Analysis, 2002, 21(3):166-170. | |

| [38] | 黄泽惠. 压裂液在人工缝网中的滞留及返排规律研究[D]. 北京: 中国石油大学(北京), 2019. |

| HUANG Zehui. Research on mechanisms of retention and flowback of fracturing fluids in artificial fracture network[D]. Beijing: China University Of Petroleum (Beijing), 2019. | |

| [39] | 徐新丽. 含微裂缝低渗储层应力敏感性及其对产能影响[J]. 特种油气藏, 2015, 22(1):127-130. |

| XU Xinli. Stress sensitivity of low-permeability reservoir containing micro-fracture and its influence on productivity[J]. Special Oil & Gas Reservoirs, 2015, 22(1):127-130. | |

| [40] | 王海柱, 沈忠厚, 李根生. 超临界CO2开发页岩气技术[J]. 石油钻探技术, 2011, 39(3):30-35. |

| WANG Haizhu, SHEN Zhonghou, LI Gensheng. Feasibility ana-lysis on shale gas exploitation with supercritical CO2[J]. Petroleum Drilling Techniques, 2011, 39(3):30-35. | |

| [41] | 齐银, 薛小佳, 戴彩丽, 等. 页岩油储层前置CO2压裂返排提高原油动用机理:以长庆油田为例[J]. 西安石油大学学报(自然科学版), 2025, 40(1):32-38. |

| QI Yin, XUE Xiaojia, DAl Caili, et al. Study on mechanism of improving recovery of shale oil by preposed CO2 fracturing:Taking Changqing Oilfield as an example[J]. Journal of Xi’an Shiyou University (Natural Science Edition), 2025, 40(1):32-38. | |

| [42] |

刘建仪, 杨雪, 刘勇. 低渗砂岩油藏CO2驱相态及组分变化规律[J]. 特种油气藏, 2022, 29(6):91-96.

doi: 10.3969/j.issn.1006-6535.2022.06.011 |

| LIU Jianyi, YANG Xue, LIU Yong. Phase state and component Change Law of CO2 flooding in low-permeability sandstone reservoirs[J]. Special Oil & Gas Reservoirs, 2022, 29(6):91-96. | |

| [43] | 张强德, 王培义, 杨东兰. 储层无伤害压裂技术——液态CO2压裂[J]. 石油钻采工艺, 2002, 24(4):47-50. |

| ZHANG Qiangde, WANG Peiyi, YANG Donglan. Fracturing technology with no damage to formation:Fluid CO2 fracture[J]. Oil Drilling & Production Technology, 2002, 24(4):47-50. | |

| [44] | 惠波, 赵博超, 杨尚儒, 等. CO2增能压裂不同生产阶段裂缝内CO2滞留碳埋存[J]. 石油与天然气化工, 2024, 53(5):84-92. |

| HUI Bo, ZHAO Bochao, YANG Shangru, et al. CO2 retention and carbon storage in fractures at different productions stages of CO2 energized fracturing[J]. Chemical Engineering of Oil & Gas, 2024, 53(5):84-92. | |

| [45] |

郭永伟, 闫方平, 王晶, 等. 致密砂岩油藏CO2驱固相沉积规律及其储层伤害特征[J]. 岩性油气藏, 2021, 33(3):153-161.

doi: 10.12108/yxyqc.20210316 |

|

GUO Yongwei, YAN Fangping, WANG Jing, et al. Characteristics of solid deposition and reservoir damage of CO2 flooding in tight sandstone reservoirs[J]. Lithologic Reservoirs, 2021, 33(3):153-161.

doi: 10.12108/yxyqc.20210316 |

|

| [46] |

王付勇, 杨坤. 致密油藏孔喉分布特征对渗吸驱油规律的影响[J]. 岩性油气藏, 2021, 33(2):155-162.

doi: 10.12108/yxyqc.20210216 |

|

WANG Fuyong, YANG Kun. Influence of pore throat size distribution on oil displacement by spontaneous imbibition in tight oil reservoirs[J]. Lithologic Reservoirs, 2021, 33(2):155-162.

doi: 10.12108/yxyqc.20210216 |

|

| [47] |

ALAAMRI J, CHANDRA V, ADDASSI M, et al. Experimental and numerical investigation of spontaneous imbibition in multilayered porous systems[J]. Energy & Fuels, 2023, 37(16):11694-11706.

doi: 10.1021/acs.energyfuels.3c01411 |

| [48] |

HU Yongquan, ZHAO Chaoneng, ZHAO Jinzhou, et al. Mechanisms of fracturing fluid spontaneous imbibition behavior in shale reservoir:A review[J]. Journal of Natural Gas Science and Engineering, 2020, 82:103498.

doi: 10.1016/j.jngse.2020.103498 |

| [49] |

ANDERSON W G. Wettability literature survey-part 2:Wettability measurement[J]. Journal of Petroleum Technology, 1986, 38:1246-1262.

doi: 10.2118/13933-PA |

| [50] | 李一波, 陈耀旺, 赵金洲, 等. 超临界二氧化碳与页岩相互作用机制[J]. 石油与天然气地质, 2024, 45(4):1180-1194. |

| LI Yibo, CHEN Yaowang, ZHAO Jinzhou, et al. Interaction mechanism between supercritical carbon dioxide and shale[J]. Oil & Gas Geology, 2024, 45(4):1180-1194. | |

| [51] |

苏伟东, 周然, 叶文勇, 等. 二氧化碳压裂机理的实验研究及矿场实践[J]. 天然气勘探与开发, 2025, 48(1):50-56.

doi: 10.12055/gaskk.issn.1673-3177.2025.01.006 |

|

SU Weidong, ZHOU Ran, YE Wenyong, et al. Experimental study and field test of CO2 fracturing mechanism[J]. Natural Gas Exploration and Development, 2025, 48(1):50-56.

doi: 10.12055/gaskk.issn.1673-3177.2025.01.006 |

|

| [52] |

LYU Peng, LIU Yu, WANG Zhe, et al. In situ local contact angle measurement in a CO2-brine-sand system using microfocused X-ray CT[J]. Langmuir, 2017, 33(14):3358-3366.

doi: 10.1021/acs.langmuir.6b04533 |

| [53] | 王欣, 李少华, 刘瑜, 等. CO2地质封存中储层岩石润湿性测量研究进展[J]. 上海理工大学学报, 2023, 45(3):205-219. |

| WANG Xin, LI Shaohua, LIU Yu, et al. A review of wettability measurement of the reservoir rock in CO2 geological storage[J]. Journal of University of Shanghai for Science and Techno-logy, 2023, 45(3):205-219. | |

| [54] | 冯东. 页岩基质压裂液渗流机理及对产气的影响研究[D]. 北京: 中国石油大学(北京), 2021. |

| FENG Dong. Study on flow mechanism of fracturing fluid in shale matrix and its effect on the gas production[D]. Beijing: China University Of Petroleum (Beijing), 2021. | |

| [55] |

刘秀婵, 陈西泮, 刘伟, 等. 致密砂岩油藏动态渗吸驱油效果影响因素及应用[J]. 岩性油气藏, 2019, 31(5):114-120.

doi: 10.12108/yxyqc.20190513 |

|

LIU Xiuchan, CHEN Xipan, LIU Wei, et al. Influencing factors of dynamic imbibition displacement effect in tight sandstone reservoir and application[J]. Lithologic Reservoirs, 2019, 31(5):114-120.

doi: 10.12108/yxyqc.20190513 |

|

| [56] | 杨柳. 压裂液在页岩储层中的吸收及其对工程的影响[D]. 北京: 中国石油大学(北京), 2016. |

| YANG Liu. Fracturing fluid imbibition into gas shale and its impact on engineering[D]. Beijing: China University of Petroleum (Beijing), 2016. | |

| [57] | LI Xiaopeng, ABASS H, TEKLU T W, et al. A shale matrix imbibition model-interplay between capillary pressure and osmotic pressure[R]. Dubai,SPE Annual Technical Conference and Exhibition, 2016. |

| [58] | 孙长宇, 王文强, 陈光进, 等. 注CO2油气藏流体体系油/水和油/气界面张力实验研究[J]. 中国石油大学学报(自然科学版), 2006, 30(5):109-112. |

| SUN Changyu, WANG Wenqiang, CHEN Guangjin, et al. Interfacial tension experiment of oil and water,oil and gas for CO2 injected reservoir fluid system[J]. Journal of China University of Petroleum (Edition of Natural Science), 2006, 30(5):109-112. | |

| [59] |

李宾飞, 叶金桥, 李兆敏, 等. 高温高压条件下CO2-原油-水体系相间作用及其对界面张力的影响[J]. 石油学报, 2016, 37(10):1265-1272.

doi: 10.7623/syxb201610006 |

|

LI Binfei, YE Jinqiao, LI Zhaomin, et al. Phase interaction of CO2-oil-water system and its effect on interfacial tension at high temperature and high pressure[J]. Acta Petrolei Sinica, 2016, 37(10):1265-1272.

doi: 10.7623/syxb201610006 |

|

| [60] | 胡君城. 返排液中离子对滑溜水性能的影响及循环使用[J]. 天然气与石油, 2020, 38(2):91-94. |

| HU Juncheng. The influence of ions in flowback liquid on slippery water and its recycling[J]. Natural Gas and Oil, 2020, 38(2):91-94. | |

| [61] |

孙会珠, 朱玉双, 魏勇, 等. CO2驱酸化溶蚀作用对原油采收率的影响机理[J]. 岩性油气藏, 2020, 32(4):136-142.

doi: 10.12108/yxyqc.20200414 |

|

SUN Huizhu, ZHU Yushuang, WEI Yong, et al. Influence mechanism of acidification on oil recovery during CO2 flooding[J]. Lithologic Reservoirs, 2020, 32(4):136-142.

doi: 10.12108/yxyqc.20200414 |

|

| [62] |

GIAMMAR D E, BRUANT R G, PETERS C A. Forsterite dissolution and magnesite precipitation at conditions relevant for deep saline aquifer storage and sequestration of carbon dioxide[J]. Chemical Geology, 2005, 217(3/4):257-276.

doi: 10.1016/j.chemgeo.2004.12.013 |

| [63] |

WANG Zijian, TANG Xuan, JING Tieya, et al. Comparison of mineral transformation in CO2 geological storage under CO2-water-sandstone and mudstone reactions[J]. Geoenergy Science and Engineering, 2024, 242:213215.

doi: 10.1016/j.geoen.2024.213215 |

| [64] | 代旭光. 页岩CO2地质封存空间演化及分子动力学作用机理:以川南地区下志留统龙马溪组页岩为例[D]. 徐州: 中国矿业大学, 2023. |

| DAI Xuguang. Space evolution of shale and molecular dyna-mics mechanism during CO2 geological sequestration:A case study of the Lower Silurian Longmaxi shales in southern Sichuan Basin[D]. Xuzhou: China University of Mining and Techno-logy, 2023. | |

| [65] | ISHIDA T, AOYAGI K, NIWA T, et al. Acoustic emission monitoring of hydraulic fracturing laboratory experiment with supercritical and liquid CO2[J]. Geophysical Research Letters, 2012, 39(16):1-6. |

| [66] | 孟照峰. 超临界二氧化碳钻井井壁岩石特性研究[J]. 石油机械, 2022, 50(7):49-54. |

| MENG Zhaofeng. Study on rock characteristics of borehole wall during supercritical carbon dioxide drilling[J]. China Petroleum Machinery, 2022, 50(7):49-54. | |

| [67] | 王海柱, 李根生, 贺振国, 等. 超临界CO2岩石致裂机制分析[J]. 岩土力学, 2018, 39(10):3589-3596. |

| WANG Haizhu, LI Gensheng, HE Zhenguo, et al. Analysis of mechanisms of supercritical CO2 fracturing[J]. Rock and Soil Mechanics, 2018, 39(10):3589-3596. | |

| [68] | 卢义玉, 廖引, 汤积仁, 等. 页岩超临界CO2压裂起裂压力与裂缝形态试验研究[J]. 煤炭学报, 2018, 43(1):175-180. |

| LU Yiyu, LIAO Yin, TANG Jiren, et al. Experimental study on fracture initiation pressure and morphology in shale using supercritical CO2 fracturing[J]. Journal of China Coal Society, 2018, 43(1):175-180. | |

| [69] | 岳立新, 孙可明. 超临界CO2增透煤微观图像重构及三维数值模拟[J]. 中国安全生产科学技术, 2017, 13(1):58-64. |

| YUE Lixin, SUN Keming. Microscopic image reconstruction and three-dimensional numerical simulation of supercritical CO2 permeability improvement coal[J]. Journal of Safety Science and Technolog, 2017, 13(1):58-64. | |

| [70] |

王香增, 孙晓, 罗攀, 等. 非常规油气CO2压裂技术进展及应用实践[J]. 岩性油气藏, 2019, 31(2):1-7.

doi: 10.12108/yxyqc.20190201 |

|

WANG Xiangzeng, SUN Xiao, LUO Pan, et al. Progress and application of CO2 fracturing technology for unconventional oil and gas[J]. Lithologic Reservoirs, 2019, 31(2):1-7.

doi: 10.12108/yxyqc.20190201 |

|

| [71] |

丁勇, 马新星, 叶亮, 等. CO2破岩机理及压裂工艺技术研究[J]. 岩性油气藏, 2018, 30(6):151-159.

doi: 10.12108/yxyqc.20180619 |

|

DING Yong, MA Xinxing, YE Liang, et al. Rock breaking me-chanism of CO2 and fracturing technology[J]. Lithologic Reservoirs, 2018, 30(6):151-159.

doi: 10.12108/yxyqc.20180619 |

|

| [72] |

SONG Xuehang, GUO Yintong, ZHANG Jin, et al. Fracturing with carbon dioxide:From microscopic mechanism to reservoir application[J]. Joule, 2019, 3(8):1913-1926.

doi: 10.1016/j.joule.2019.05.004 |

| [73] | 卢伟, 张华, 韩永亮, 等. 页岩油前置超临界二氧化碳压裂造缝技术[J]. 油气井测试, 2023, 32(1):38-44. |

| LU Wei, ZHANG Hua, HAN Yongliang, et al. Prepad supercritical carbon dioxide fracturing technology in shale oil reservoir[J]. Well Testing, 2023, 32(1):38-44. | |

| [74] | 马力, 欧阳传湘, 谭钲扬, 等. 低渗透油藏CO2驱中后期提效方法研究[J]. 岩性油气藏, 2018, 30(2):139-145. |

| MA Li, OUYANG Chuanxiang, TAN Zhengyang, et al. Efficiency improvement of CO2 flooding in middle and later stage for low permeability reservoirs[J]. Lithologic Reservoirs, 2018, 30(2):139-145. | |

| [75] |

杨楷乐, 何胜林, 杨朝强, 等. 高温-超压-高CO2背景下致密砂岩储层成岩作用特征:以莺歌海盆地LD10区新近系梅山组—黄流组为例[J]. 岩性油气藏, 2023, 35(1):83-95.

doi: 10.12108/yxyqc.20230108 |

|

YANG Kaile, HE Shenglin, YANG Zhaoqiang, et al. Diagenesis characteristics of tight sandstone reservoirs with high temperature,overpressure and high CO2 content:A case study of Neogene Meishan-Huangliu Formation in LD10 area,Yinggehai Basin[J]. Lithologic Reservoirs, 2023, 35(1):83-95.

doi: 10.12108/yxyqc.20230108 |

|

| [76] |

TAO Jiaping, MENG Siwei, LI Dongxu, et al. Research on evolutionary laws of mechanical properties and pore structure during CO2 pre-injection fracturing in shale reservoirs[J]. Energies, 2024, 17(11):2470.

doi: 10.3390/en17112470 |

| [77] | 游利军, 康毅力, 陈一健, 等. 致密砂岩气藏水相圈闭损害实验研究及应用[J]. 钻井液与完井液, 2006, 23(2):4-7. |

| YOU Lijun, KANG Yili, CHEN Yijian, et al. Experiments and applications of water phase trapping in tight gas sand reservoirs[J]. Drilling Fluid & Completion Fluid, 2006, 23(2):4-7. | |

| [78] | 赵景原, 孙玉学, 冯福平, 等. 水相圈闭损害机理、评价及防治措施研究进展[J]. 非常规油气, 2018, 5(5):104-110. |

| ZHAO Jingyuan, SUN Yuxue, FENG Fuping, et al. Research advances of aqueous phase trapping-damage mechanism,evaluation and prevention method[J]. Unconventional Oil & Gas, 2018, 5(5):104-110. | |

| [79] | 游利军. 致密砂岩气层水相圈闭损害机理及应用研究[D]. 成都: 西南石油学院, 2004. |

| YOU Lijun. The study of mechnisms of aqeous phase trapping and its applications in tight sands gas reserviors[D]. Chengdu: Southwest Petroleum Institute, 2004. | |

| [80] | BENNION D B, THOMAS F B, BIETZ R F, et al. Remediation of water and hydrocarbon phase trapping problems in low permeability gas reservoirs[J]. Journal of Canadian Petroleum Technology, 1999, 38(8):39-47. |

| [81] | BENNION D B, THOMAS F B, BIETZ R F, et al. Water and hydrocarbon phase trapping in porous media-diagnosis,prevention and treatment[J]. Journal of Canadian Petroleum Techno-logy, 1996, 35(10):29-36. |

| [82] | 崔迎春, 张琰. 低渗透气藏地层损害的特殊性[J]. 钻井液与完井液, 1998, 15(2):11-13. |

| CUI Yingchun, ZHANG Yan. The particularity of formation damage in low-permeability gas reservoirs[J]. Drilling Fluid & Completion Fluid, 1998, 15(2):11-13. | |

| [83] | 张舵. CO2压裂液的研究进展、挑战与未来展望[J]. 科技创新与应用, 2025, 15(2):106-109. |

| ZHANG Duo. Research progress,challenges and future prospects of CO2 fracturing fluid[J]. Technology Innovation and Application, 2025, 15(2):106-109. | |

| [84] |

郭建春, 詹立, 苟波, 等. 不同相态二氧化碳前置酸压碳酸盐岩裂缝形成规律[J]. 石油勘探与开发, 2021, 48(3):639-645.

doi: 10.11698/PED.2021.03.19 |

| GUO Jianchun, ZHAN Li, GOU Bo, et al. Formation of fractures in carbonate rocks by pad acid fracturing with different phases of carbon dioxide[J]. Petroleum Exploration and Deve-lopment, 2021, 48(3):639-645. | |

| [85] | 张矿生, 齐银, 薛小佳, 等. 鄂尔多斯盆地页岩油水平井CO2区域增能体积压裂技术[J]. 石油钻探技术, 2023, 51(5):15-22. |

| ZHANG Kuangsheng, QI Yin, XUE Xiaojia, et al. CO2 regional enhanced volumetric fracturing technology for shale oil horizontal wells in Ordos Basin[J]. Petroleum Drilling Techniques, 2023, 51(5):15-22. | |

| [86] |

刘合, 黄有泉, 蔡萌, 等. 松辽盆地古龙页岩油储集层压裂改造工艺实践与发展建议[J]. 石油勘探与开发, 2023, 50(3):603-612.

doi: 10.11698/PED.20230191 |

|

LIU He, HUANG Youquan, CAI Meng, et al. Practice and development suggestions of hydraulic fracturing technology in the Gulong shale oil reservoirs of Songliao Basin,NE China[J]. Petroleum Exploration and Development, 2023, 50(3):603-612.

doi: 10.1016/S1876-3804(23)60413-6 |

|

| [87] |

张治恒, 田继军, 韩长城, 等. 吉木萨尔凹陷芦草沟组储层特征及主控因素[J]. 岩性油气藏, 2021, 33(2):116-126.

doi: 10.12108/yxyqc.20210212 |

|

ZHANG Zhiheng, TIAN Jijun, HAN Changcheng, et al. Reservoir characteristics and main controlling factors of Lucaogou Formation in Jimsar Sag,Jungger Basin[J]. Lithologic Reservoirs, 2021, 33(2):116-126.

doi: 10.12108/yxyqc.20210212 |

|

| [88] | 李柏杨. 吉木萨尔页岩油储层CO2前置蓄压裂增产机理研究[D]. 北京: 中国石油大学(北京), 2023. |

| LI Baiyang. Investigation into stimulation mechanism of CO2 pre-pad energized fracturing in Jimusar shale oil reservoir[D]. Beijing: China University Of Petroleum (Beijing), 2023. | |

| [89] |

雷征东, 孟思炜, 彭颖锋, 等. 古龙页岩油二氧化碳前置压裂适应性评价[J]. 石油勘探与开发, 2025, 52(2):408-418.

doi: 10.11698/PED.20240765 |

|

LEI Zhengdong, MENG Siwei, PENG Yingfeng, et al. Evaluation of the adaptability of CO2 pre-fracturing to Gulong shale oil reservoirs[J]. Petroleum Exploration and Development, 2025, 52(2):408-418.

doi: 10.1016/S1876-3804(25)60575-1 |

| [1] | 张庆福, 张世明, 曹小朋, 吕琦, 李宗阳, 于金彪, 汪勇. 页岩油藏CO2吞吐渗流场-应力场耦合数值模拟方法[J]. 岩性油气藏, 2026, 38(1): 172-179. |

| [2] | 梁锋, 曹哲. 鄂尔多斯盆地华池地区三叠系长7页岩油储层特征、形成环境及富集模式[J]. 岩性油气藏, 2025, 37(1): 24-40. |

| [3] | 钱永新, 赵毅, 刘新龙, 刘鸿, 刘国梁, 朱涛, 邹阳, 陈方文. 玛湖凹陷二叠系风城组页岩油储层特征及高产主控因素[J]. 岩性油气藏, 2025, 37(1): 115-125. |

| [4] | 吴佳, 赵卫卫, 刘钰晨, 李慧, 肖颖, 杨迪, 王嘉楠. 鄂尔多斯盆地延安地区三叠系长7页岩源储配置及油气富集规律[J]. 岩性油气藏, 2025, 37(1): 170-181. |

| [5] | 白玉彬, 李梦瑶, 朱涛, 赵靖舟, 任海姣, 吴伟涛, 吴和源. 玛湖凹陷二叠系风城组烃源岩地球化学特征及页岩油“甜点”评价[J]. 岩性油气藏, 2024, 36(6): 110-121. |

| [6] | 洪智宾, 吴嘉, 方朋, 余进洋, 伍正宇, 于佳琦. 纳米限域下页岩中可溶有机质的非均质性及页岩油赋存状态[J]. 岩性油气藏, 2024, 36(6): 160-168. |

| [7] | 王子昕, 柳广弟, 袁光杰, 杨恒林, 付利, 王元, 陈刚, 张恒. 鄂尔多斯盆地庆城地区三叠系长7段烃源岩特征及控藏作用[J]. 岩性油气藏, 2024, 36(5): 133-144. |

| [8] | 徐田录, 吴承美, 张金凤, 曹爱琼, 张腾. 吉木萨尔凹陷二叠系芦草沟组页岩油储层天然裂缝特征与压裂模拟[J]. 岩性油气藏, 2024, 36(4): 35-43. |

| [9] | 何文渊, 赵莹, 钟建华, 孙宁亮. 松辽盆地古龙凹陷白垩系青山口组页岩油储层中微米孔缝特征及油气意义[J]. 岩性油气藏, 2024, 36(3): 1-18. |

| [10] | 邵威, 周道容, 李建青, 章诚诚, 刘桃. 下扬子逆冲推覆构造后缘凹陷油气富集关键要素及有利勘探方向[J]. 岩性油气藏, 2024, 36(3): 61-71. |

| [11] | 计玉冰, 郭冰如, 梅珏, 尹志军, 邹辰. 四川盆地南缘昭通示范区罗布向斜志留系龙马溪组页岩储层裂缝建模[J]. 岩性油气藏, 2024, 36(3): 137-145. |

| [12] | 曹江骏, 王茜, 王刘伟, 李诚, 石坚, 陈朝兵. 鄂尔多斯盆地合水地区三叠系长7段夹层型页岩油储层特征及主控因素[J]. 岩性油气藏, 2024, 36(3): 158-171. |

| [13] | 白雪峰, 李军辉, 张大智, 王有智, 卢双舫, 隋立伟, 王继平, 董忠良. 四川盆地仪陇—平昌地区侏罗系凉高山组页岩油地质特征及富集条件[J]. 岩性油气藏, 2024, 36(2): 52-64. |

| [14] | 邓远, 陈轩, 覃建华, 李映艳, 何吉祥, 陶鑫, 尹太举, 高阳. 吉木萨尔凹陷二叠系芦草沟组一段沉积期古地貌特征及有利储层分布[J]. 岩性油气藏, 2024, 36(1): 136-144. |

| [15] | 刘海磊, 朱永才, 刘龙松, 尹鹤, 王学勇, 杜小弟. 准噶尔盆地阜康断裂带上盘二叠系芦草沟组页岩油地质特征及勘探潜力[J]. 岩性油气藏, 2023, 35(4): 90-101. |

|

||

甘公网安备 62010202002827号

甘公网安备 62010202002827号